Modular Logistics Vehicle

United States Marine Corps

The US Marine Corps was looking for a way to solve multiple problems with their existing on-base vehicles and were interested in testing out a new way to design and build products, Co-creation.

Through a process of rigorous fact-finding, innovative brainstorming, and a global community of creatives, we were able to produce a completely modular system that exceeded expectations and opened a new wave of innovation for the military.

More than just user focused…user led

Understanding the full scope of the problem requires insights that are only clear when talking to users.

In this case, we went to the 29 Palms base and spoke with Marines who drove us around to show the full scope of everything they experienced. The way that they use vehicles on base, the jobs that they needed to do, and the obstacles that kept them from doing those jobs. This helped create a scope for the project where we were able to create several personas and broad categories for solutions.

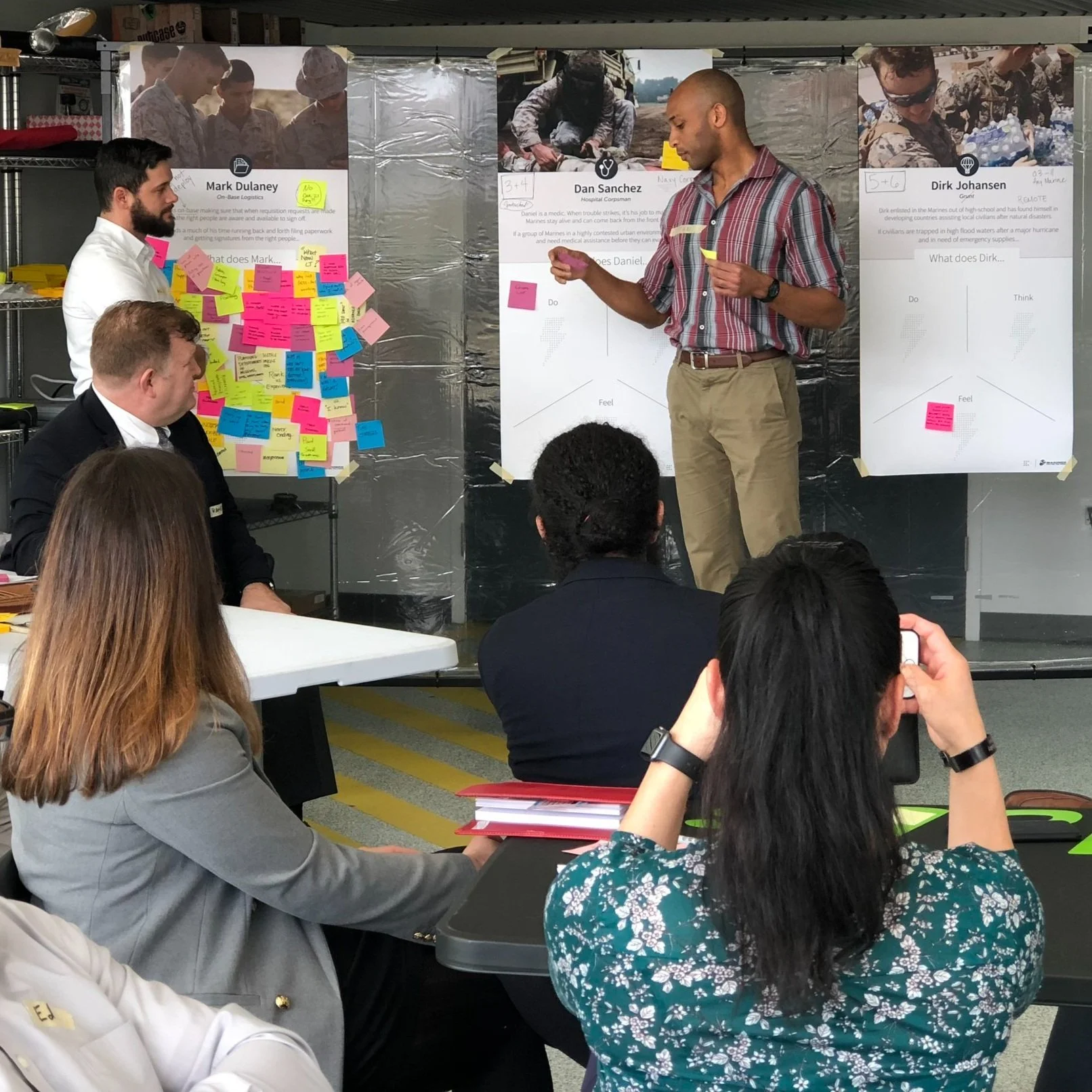

We then hosted an innovation workshop, with both officers and enlisted Marines to help build out the specific personas and brainstorm on several solution categories followed by some hands-on making to see if any trends appeared in their ideation.

Blueprints for success

With the audience fully understood and the needs of the vehicle determined, a project blueprint was created. This came with a pretty specific change in direction. The original ask was for a “Tactical Mobility Vehicle,” but through our research we realized the bigger need was for a modular on-base vehicle.

The project blueprint included fully built-out user personas, detailed use cases, clearly defined timelines, outreach plans, and more.

Providing this blueprint helped ensure that everyone, from the project managers to the top brass, was on board with exactly how we planned to create this exciting innovation.

More ideas lead to better solutions

The design for the MLV utilized the process of co-creation, where a global community of industrial designers collaborate throughout the ideation phases and then compete in two design challenges.

With more than 100 valid designs submitted, the final design was called the HAT 2.0 and featured four removable box designs (transportation, administrative, mechanical repair, and construction) on an electric base.

The judging process included several active and former members of the Marines as well as engineers from the build partner, Fathom, who helped ensure that not only were the designs meeting the specifications for the USMC but also that the design could be feasibly prototyped.

Measuring Success

With the success of the design phase of the project, we were tasked with creating a rapid prototype to show that not only were we able to deliver innovative designs, but, when paired with a solid engineering team, we could create a product that worked.

Fathom provided the engineering and production for the proof-of-concept build consisting of a platform and two modules, while Local Motors showed how large-scale 3D printing could quickly create additional modules depending on need.

With hundreds of concepts, working full-scale prototypes, and hundreds of thousands of people engaging with the project online, the USMC found the project to be overwhelmingly successful.

This first project opened up entirely new paths of revenue for Local Motors as the USMC partnered to explore additional open-innovation projects as well as developing new nano-manufacturing facilities for remote development.